(Spiral wound gasket category)HY-805 GRAPHITE GASKET

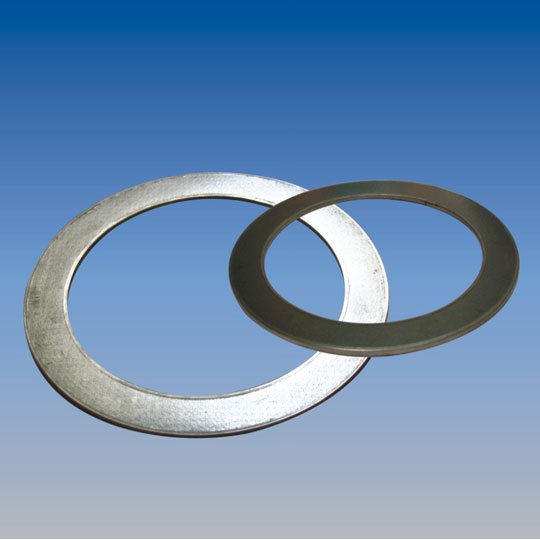

Reinforced Graphite Gasket(SS Tanged Graphite Gasket)

It is made from graphite as homogeneous, reinforced by metal mesh, foil or tanged metal. Laminated

from compressed layers of purified natural graphite flake, and mechanically bonded with the stainless

steel tangs, ensures the material retains dimensional stability in high temperatures. In addition the material

seals easily under moderate bolt loads offering torque retention through service and sealing tightly even

during pressure fluctuations. Reinforced graphite gasket offers excellent sealing capabilities such as thermal

stability, self-lubrication, corrosion resistance, without being brittle and aging etc., under extreme conditions

with a longer life and less maintenance. It offers a high level of resistance to aggressive chemicals and its ability

to withstand high pressures and extreme temperatures, up to 650°C in steam, makes it ideal for a wide range

of applications.

Application:

It has very good sealing performance, low preloaded pressure, and not sticking to the flange sealing surface; used in

the flange surface sealing of pipeline, valve, pump, pressure containers, heat exchanger, and reaction cauldron, etc.

The film sticking PTEE can be used in food, pure water, and pharmacy sections.

Technique Specification:

1).Working temperature: -200℃~650℃

2).Working pressure: 6.4~10.0MPa

3).Min. Pre-tightening specific pressure: y=30MPa

4).Gasket coefficient: m=2

5).Max.machinable size: ~2100mm

Main Style:

1.Flexible Expanded Grahite Gasket

2.Reinforced Graphite Gasket With Inner Eyelet

3.Reinforced Graphite Gasket With Outer Eyelet

4.Reinforced Graphite Gasket With Outer Eyelet & Inner eyelet

The biggest size:OD=<2100mm (Special size can also be made as request.)

扫码关注我们

扫码关注我们