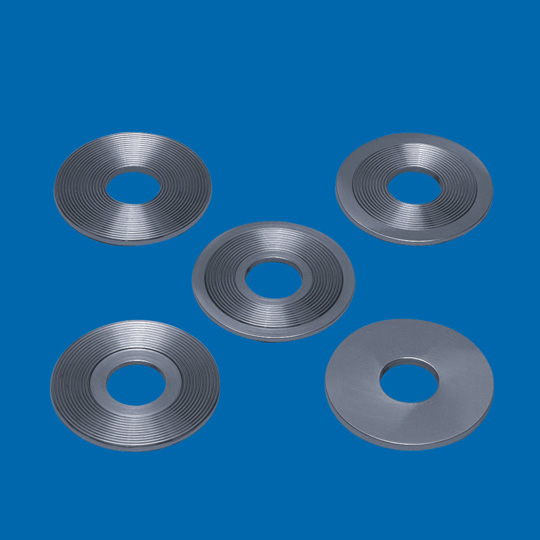

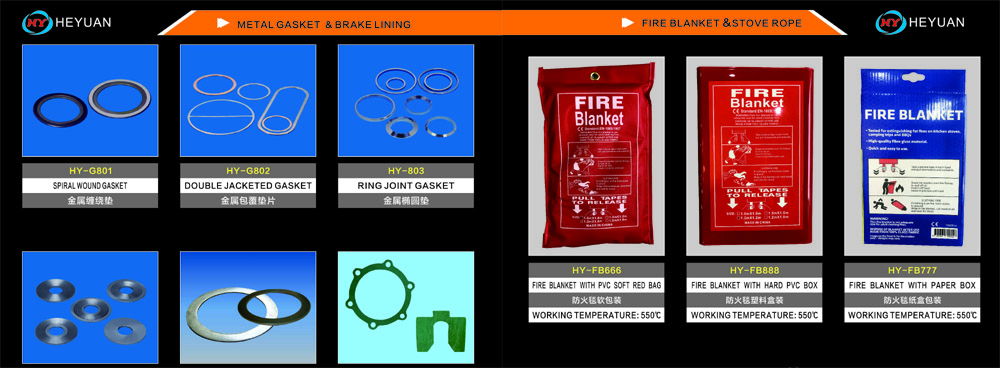

HY-804 SERRATED METAL GASKET(Spiral wound gasket category)

Serrated metal gasket selection of mild steel, carbon steel, copper, stainless steel, chromium steel, monel alloy steel, alloy of aluminum and other metal plate or rod by mechanical processing, surface processing into a 90angle between the ring gear. Can increase the inner, outer ring position. In order to protect the sealing flange and effective, you can paste in the gasket sealing surface layer, the material choice of PTFE, graphite and so on.

Power plants (or nuclear power) Steam generators, marine generators in the heat exchanger or pipe flange gasket sealing gaskets, manhole gaskets, also can be used in chemical industry high temperature and high pressure sealing location.

Serrated Metal Gasket

1.process the metal flat gasket to teeth-shaped metal gasket of 90°contained angle. Internal and external positioning ring. To protect flange and ensure effective sealing, the surface sealing layer can be adhibited. The materials may be PTEE, graphite, and specially-processed silver and aluminum.

2. choosing materials

Soft steel, copper, silver, stainless steel, chrome steel, Monel alloy steel, alloy aluminum and other metal slabs or sticks are processed to be ring teeth-shaped surface after mechanical processing.

3. relevant data

Maximum operation pressure: 250Kg/cm3

Minimum preloaded specific pressurey>Kg/cm3700 Kg/m3

Gasket Coefficientm >4.25

Maximum processing dimension: 3000MM

4. application range

Steam dynamo of power plant (or nuclear power plant), heat exchanger gasket or fully-sealing gasket of shipping dynamo and manhole gasket can be used in the high temperature and high pressure of chemical industry.

5. production reference (mm)

Outer diameter of gasket gasket thickness T chimb thickness t distance between tooth peak P

扫码关注我们

扫码关注我们